Personal project, 2017

Off-road motorcycle riding in extreme terrain requires constant modulation of the clutch lever. Consequently, a stiff clutch can quickly induce rider fatigue. A low-cost, 3D-printed solution was sought to reduce the lever effort on my personal motorcycle by altering the mechanical advantage of the lever itself.

Actions:

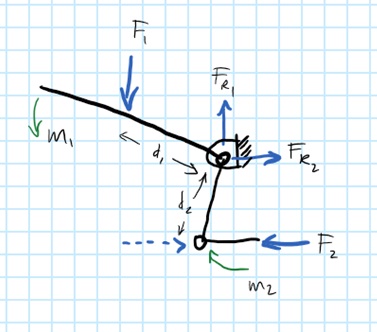

As the master cylinder’s geometry was fixed, the simplest solution was to design and manufacture a new lever with reduced distance between the lever’s pivot point and the master cylinder plunger’s pivot point. However, any alteration of this distance would incur an increase of radial force on the master cylinder, which would increase friction and cylinder wear. To bring the plunger pivot point in line with the master cylinder axis, the lever pivot point was relocated closer to the cylinder by the addition of a second part, a 3D-printed bracket.

Results:

The new geometry resulted in approximately 40% reduction in clutch effort, with a corresponding reduction in rider fatigue.