Alta Motors, 2018

As a nascent product made primarily of aluminum alloys, Alta’s motorcycle fatigue life and yield load were a concern. Rudimentary fatigue testing was in place, but an automated, hydraulically-actuated test was desired in order to more accurately control testing parameters and to generate more detailed results.

Actions:

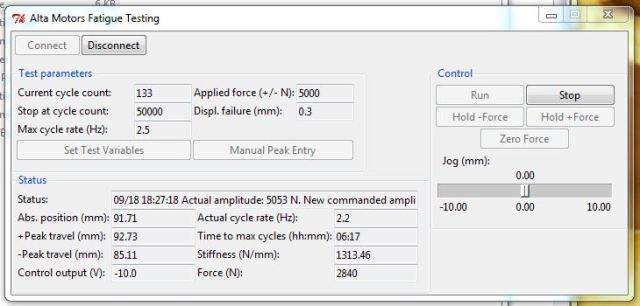

I attended hydraulic controls training, then used this knowledge to develop a Python fatigue testing application. The application featured a graphical user interface, live data acquisition, and an auto-tuning algorithm to ensure target forces were maintained at the maximum possible cycle speed. Fatigue was assessed by examining displacement sensor data at a given force value.

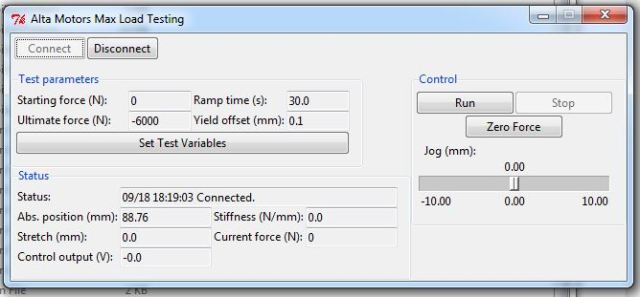

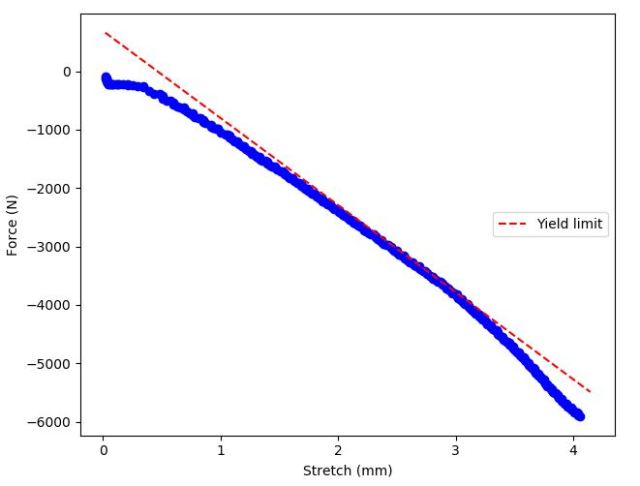

I applied similar hydraulic control and data acquisition principles to an automated tensile and compressive yielding test. I developed a Python application to live-plot sensor data and perform a linear regression analysis to assess when force and displacement data left a linear trajectory, indicating yield.

Results:

The tests I developed allowed for benchmarking of competitors’ products. This data, and the characterization of Alta’s own products, was to influence the design of an upcoming Alta Motors motorcycle chassis.