Shockwave Seats, 2016

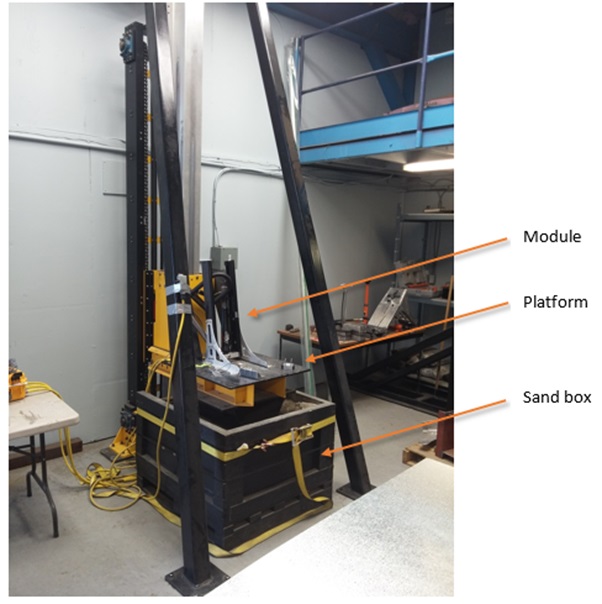

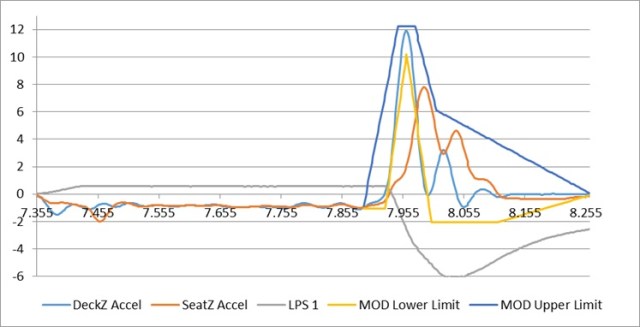

Performance testing of marine suspension seating entails dropping a test seat with various loads and from various heights into a pit of sand, simulating the impact experienced by a vessel in rough seas. Accelerometers record the input acceleration and seat acceleration, and the difference between these values qualifies product performance.

Tasked with testing new and existing products, I saw an opportunity to standardize the testing methodology and to automate the data collection and analysis process.

Actions:

For an objective performance comparison across products, I implemented a drop testing performance metric as described by the British Ministry of Defense. This metric specifies a number of drops with several different loads, and stipulates a validity envelope for input acceleration. A mathematical formula is applied to the collected peak seat acceleration values, yielding an objective overall score for the tested product.

Processing raw data in this fashion would be time consuming, so I developed a comprehensive Excel macro workbook that would automatically import data from each drop as it completed, analyze the input acceleration to ensure validity of conditions, show a plot of the captured data, and compute the objective testing score.

I then wrote a drop testing manual with instructions for operating the drop testing equipment and processing the resulting data with my Excel macro workbook.

Results:

Consistent testing methodology was established which allowed for objective comparison of products. This allowed the sales and marketing team to accurately describe the performance of the existing product lineup, and allowed the engineering team to quantify the success of new product developments.

Automation of data collection and analysis vastly reduced the time required for comprehensive product testing, with consequent reduction of research and development costs.