Verdant Robotics, 2022

A new generation of up-sized robotic crop sprayers necessitated a multi-channel hydraulic actuation solution to maintain its wings at a consistent height above ground. To better align the engineering and business timelines, an interim solution of passive, sequenced hydraulics and ground-following gauge wheels was to fill in the immediate need, before a fully-automated design with closed-loop sensor feedback could be realized.

This was a very interesting and challenging project that allowed me to greatly develop my skills in hydraulic system design and control.

Actions:

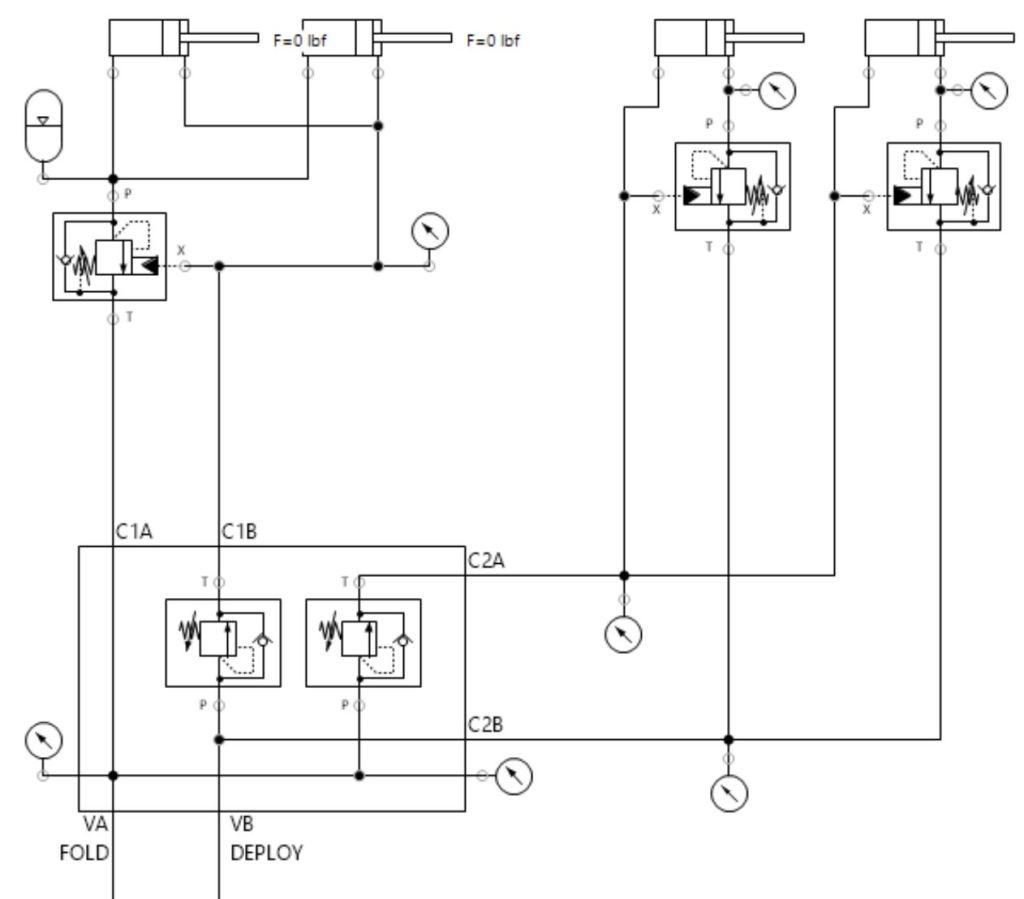

To begin, I studied relevant texts in the field of hydraulic actuation and control, and tapped into my professional network of experts on the subject. I used this guidance to create a fully passive, fail-safe, sequenced hydraulic circuit with one-lever actuation to coordinate movement of multiple actuators.

I simulated this design in Festo FluidSIM to validate, then worked with vendors to procure a set of prototype hardware.

I then assembled, tested, tuned, and validated a physical manifestation of this circuit and confirmed its successful operation.

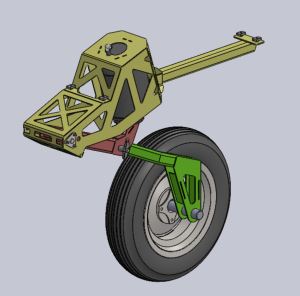

I also designed a removable gauge wheel assembly with height-adjustable pneumatic suspension, and constructed a prototype.

Results:

The design was successfully prototyped and validated. As of this writing, this interim solution is available for deployment on the first wide-coverage robot that Verdant Robotics will produce.