Verdant Robotics, 2022

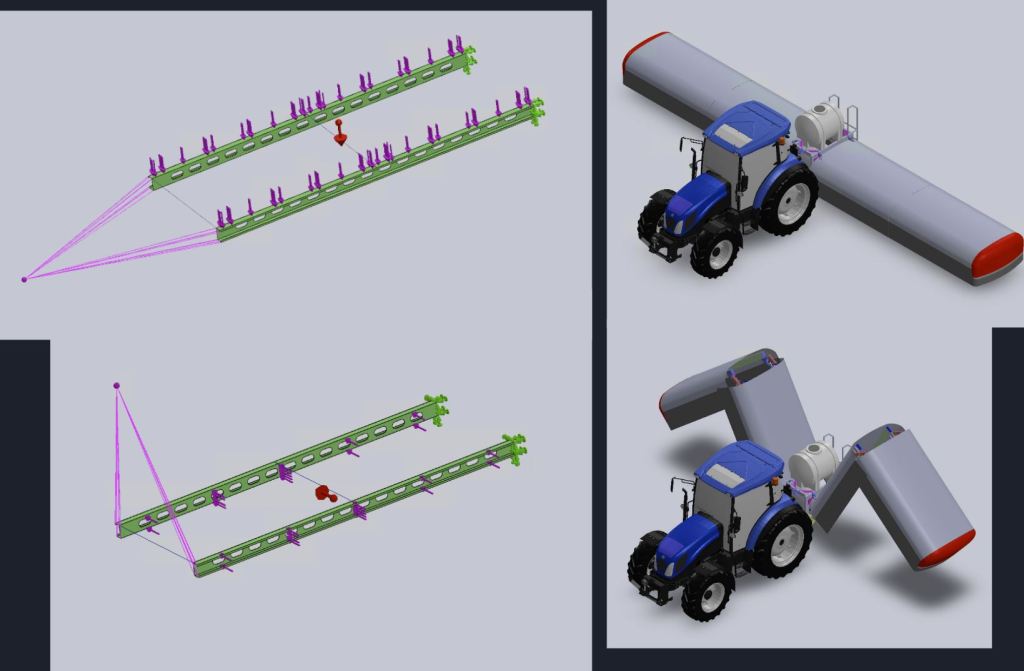

Building on the success of a 20′ wide robotic spraying platform, Verdant Robotics wished to create a 40′ wide robot with-all new construction, with specific focus on Design for Manufacturing (DFM) and Design for Assembly (DFA).

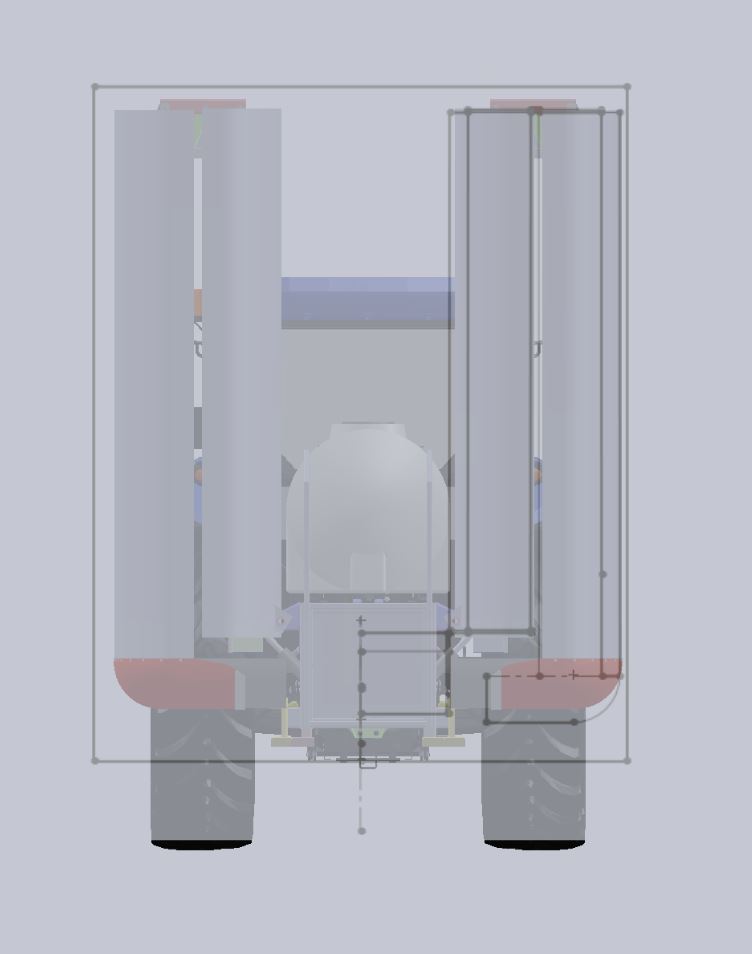

One of the key constraints on the design was a maximum shipping dimension which necessitated multiple folding axes so as not to qualify as an oversized load when in transit.

Actions:

Working with the size and required locations of vision and spraying components, several concepts were generated. Ultimately, a bi-fold mechanism was selected due to its compact nature and inherent shipping protection for internally-housed components.

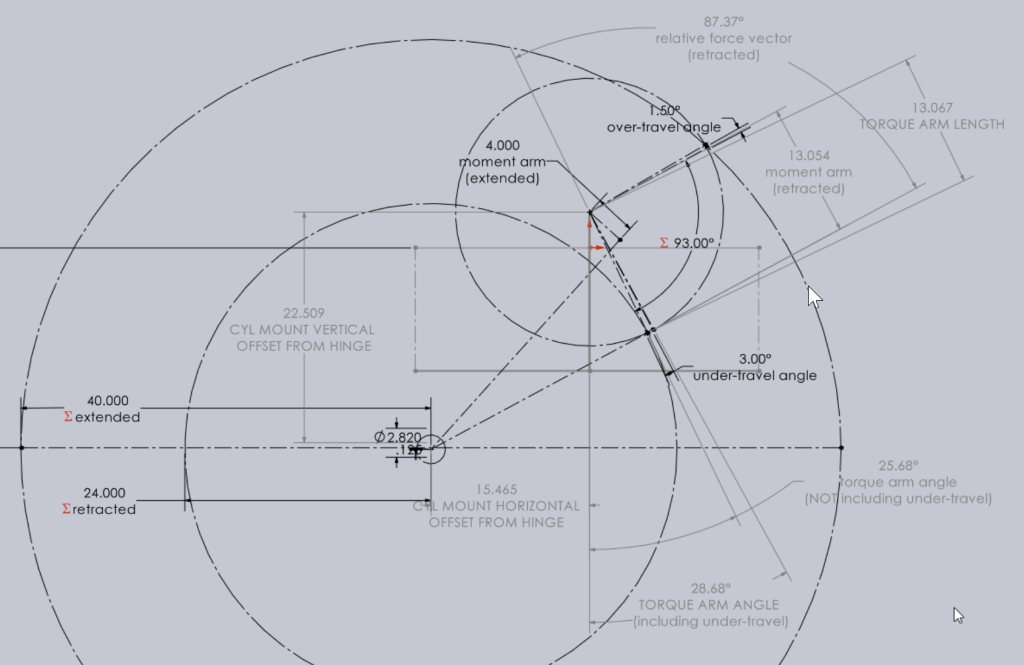

Using simplified 2D sketches, hinge locations were established.

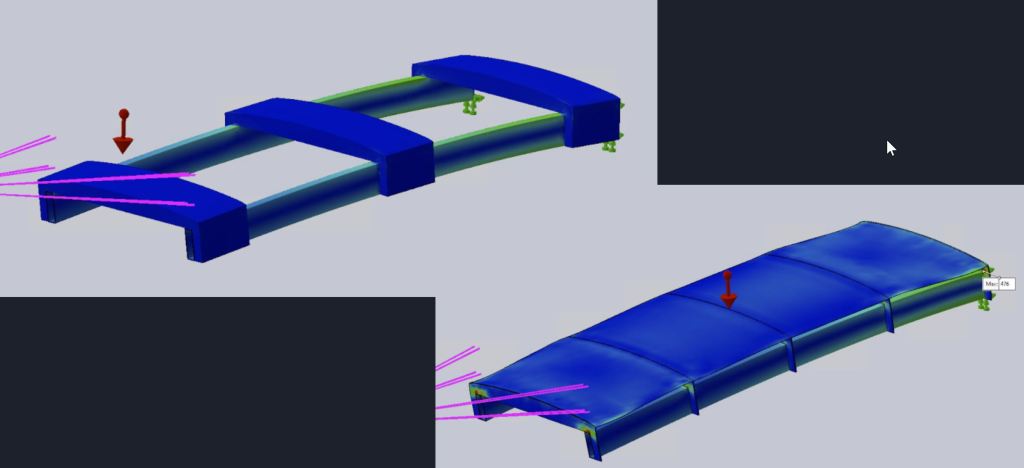

The structure was designed to mimic an aircraft wing, with load-bearing spars and ribs lying under a thin, stressed skin. To optimize the spar and rib geometry, a Finite Element Analysis (FEA) was set up in SolidWorks Simulation. The conditions for the FEA were taken from real-world accelerometer data captured from Verdant’s working robots. Two configurations were tested, meant to simulate worst-case loading scenarios: wings fully deployed to their 40′ width (maximum cantilever bending), and longitudinal acceleration with wings partly folded (maximum twist).

Iterative design/simulation was used to independently optimize spar, rib, and skin geometry, maximizing stiffness and minimizing mass.

With a structural design in place, attention was shifted to joint kinematics. I built a simplified 2D sketch to try different concepts and geometries, leading to an optimized design that packaged well and required minimum hydraulic force to actuate.

Results:

The first 40′ robot chassis was completed in early 2023. As a result of the DFM and DFA design strategy, assembly was completed approximately 80% faster than previous designs. As of this writing, validation and deployment of this chassis is pending.